Comprehensive truck tyre maintenance from Horndean Tyres

Since 1980, Horndean Tyres have focused on providing the best tyre maintenance services for every operator of commercial vehicles.

We understand that every business relies on their commercial vehicle fleet for the safe and timely distribution of their goods, passengers and services. Horndean Tyres are here to support this mission by maximising vehicle uptime for all your HGVs, rigid trucks, tractor units, HGV trailers, PSVs, buses, coaches and vans.

Our team of skilled tyre technicians take pride in providing a lifecycle of comprehensive tyre maintenance and tyre services:

- Regrooving commercial tyres

- Tyre pressure correction

- Safe puncture and damage repairs

- Turning on the rim

- Wheel rotation

- Twinning dual wheel assemblies

- Wheel alignment service

All designed to ensure your fleet remains operational, safe and compliant on every journey.

Horndean Tyres offer two options for on-site commercial tyre maintenance:

Proactive tyre management

Our proactive tyre management is a preventative maintenance service. Our skilled tyre technicians will regularly perform detailed inspections of all your tyres during your commercial vehicles scheduled downtime. These inspections are proven to identify issues that we can rectify with our tyre maintenance services before they escalate. Our in-depth knowledge and familiarity of your fleet will systematically extend tyre service life and optimise fleet performance.

Responsive service

Our responsive service gives you access to our full range of tyre maintenance services. Simply contact us with the tyre maintenance service required and we will arrange a convenient appointment with you. Our team of skilled tyre technicians will rectify the issue at hand and report any additional actions that should be performed before they escalate. All designed to maximise tyre service life and keep your vehicles safe.

SERVICE YOU CAN RELY ON

Regrooving commercial tyres

Our team of truck tyre technicians are fully trained to regroove commercial tyres in accordance with the manufacturer’s specification.

Regrooving should be performed when the original tread is 3-4mm deep. We start with a thorough inspection of the tread and casing to make sure they are in good condition and only display regular wear. We then carefully regroove the original tread pattern and perform a final check before refitting. Regrooving extends tyre service life by 15-20% without any compromise on safety or performance.

Tyre pressure correction

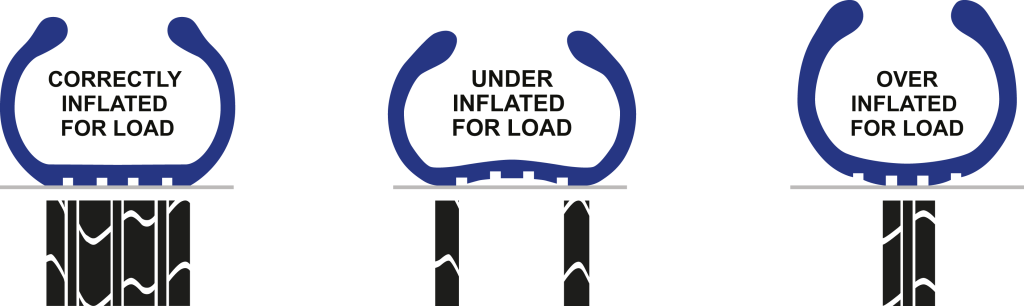

The tyre and wheel assembly is engineered to hold the high-pressure air that supports the vehicle’s combined weight. This makes air the critical component in the service life of every commercial tyre.

However, tyre casings and valves can never be totally airtight – you should expect a pressure loss of 3% every month. Our highly trained tyre technicians can detect incorrect pressure when the tyres are cold during our routine inspections. These inspections can also highlight slow punctures, which left unchecked will deteriorate and cause inconvenient downtime and unnecessary cost later.

Tyres running at the correct air pressure will optimise the vehicles handling, braking and stability for the driver. The tyres will also experience the lowest friction and rolling resistance with the road surface – extending tyre service life whilst reducing fuel consumption and carbon emissions.

Safe puncture and damage repairs

The key to any puncture repair is that the pressure loss is detected quickly, for example in the drivers daily walkaround check, so that the tyre is not driven on when flat.

Our qualified truck tyre technicians will remove the tyre from the wheel rim to enable careful examination. If the tread and casing are found to be in good condition and undamaged, we repair the puncture in accordance with British Standard AU 159. Horndean Tyres only use high-quality materials to ensure that all minor repairs are safe and long-lasting.

If the tyre has damage beyond the scope of our on-site repair service, we can send it away to our specialist tyre partner for a major repair. After thorough checks, they can determine if a complete vulcanised repair is possible. A vulcanised repair will allow the tyre to continue in operation for the remainder of its designed service life.

Turning on the rim

Our detailed tyre inspections are designed to identify tyres that can benefit from routine maintenance. We recommend turning on the rim if the tyre has excessive shoulder wear or sidewall abrasion – all caused through routine day-to-day operation.

Turning on the rim involves removing the tyre from the wheel and remounting it with the outer sidewall repositioned to the inside of the wheel. This will even out the tyre wear to enable the tread to come back to a consistent depth and protects the sidewall from further abrasion. Turning on the rim prevents premature replacement of the tyre and ensures the casing is suitable for retreading at the end of its service life.

Wheel rotation

Our team of highly trained tyre technicians are experts at maximising tyre service life across vehicle fleets. Our tyre inspections and experience will identify tyres that can benefit from wheel rotation to encourage even wear.

Wheel rotation involves relocating wheels from one axle to another, and even between vehicles if suitable and safe. The tyres on steer axle always experience greater wear as they work hardest. A timely wheel rotation to the slower-wearing lift axle is more cost effective than letting the tyre wear out and replacement. We recommend regrooving the steer tyres at the time of relocation to drive extra value. Similarly, on triaxle trailers the tyres on the rear most axle experience the greatest wear. A relocation to the slower-wearing middle axle will proactively manage the differing rates of wear.

Twinning dual wheel assemblies

Twinning involves carefully matching the tread depth on vehicles with twin wheel or dual wheel assemblies. We always recommend there is less than 5mm variation on tyres across the same axle. These ‘twinned’ tyres will extend tyre service life and optimise vehicle safety.

Vehicles are fitted with dual wheel assemblies to increase the payload available. If any of these four tyres feature lower tread depths the weight load on the tyres with more tread will be increased. This creates extra friction with the road that generates excessive heat and accelerates tyre wear. Left unchecked, this build-up of heat can damage the tyre which will prevent regrooving and retreading in the future – or provoke an uncontrolled tyre failure during operation.

Commercial tyre wheel alignment service

When our skilled tyre technicians detect uneven tread wear this can be a consequence of incorrect wheel alignment. Your commercial wheels become out of alignment for a variety of reasons – from impact with potholes or debris on the road, to the nudging of roadside kerbs.

Correct wheel alignment will optimise the vehicles handling for the driver. It will also reduce rolling resistance which will extend tyre service life and minimise both fuel consumption and carbon emissions.

With most new commercial vehicles sourced on full Repair and Maintenance contracts we typically report the defect for your OEM service provider to remedy at the next planned maintenance. Alternatively, we recommend our specialist service partner who provides a dedicated commercial wheel alignment service on your premises. Their skilled alignment technicians use calibrated laser technology to realign your steering and trailer axles to the manufacturer’s specification.

Commercial vehicles tyres and the law

There are many legal requirements relating to the condition and use of tyres on commercial vehicles.

- It is illegal to run a commercial vehicle with a tyre at the wrong pressure.

- It is illegal to run a tyre that has a cut longer than 25mm (or 10% of the section of the tyre, whichever is greater) or deep enough to reach the ply or cords.

- It is illegal to use a tyre with a lump, bulge or tear, or with any of the cords exposed.

- The tyre grooves must have a depth of at least 1mm around the whole circumference and across three quarters of the breadth of the tread. If the original tread pattern was only across three-quarters of the tread width, all grooves must be at least 1mm deep.

Staying within the law can be complicated. At Horndean Tyres we know the law and keep up-to-date with developments and new legislation. With our proactive tyre management and your drivers daily walkaround checks, we’ll keep your fleet’s tyres legal.

Safety

Skilled and compliant tyre technicians

Our highly skilled truck tyre technicians have years of knowledge and expertise gained from working with a diverse selection of commercial vehicles. Working from your local Horndean Tyres service centre they will become familiar with your fleet. Operationally, this knowledge and understanding will allow them to become a trusted part of your fleet management and maintenance team.

Horndean Tyres invest in training to ensure we are fully compliant with accredited industry standards, including the City & Guilds Licence to Fit programme, the NTDA Licensed Commercial Tyre Technician and REACT Roadside Emergency Licences.

This ensures Horndean Tyres have a consistently skilled workforce that will minimise avoidable tyre risk in your commercial fleet.

Robust and safe procedures

Safety is always Horndean Tyres top concern. Doing things safely means doing things correctly. Our robust work procedures and policies are carefully defined to ensure we consistently perform our fleet tyre services in a rigorous and methodical process.

We create a safe work environment with health and safety compliant to current legislation. The safety of our tyre technicians is paramount as they work across a range of premises, from the relative safety of your depots and vehicle service centres, to working next to the roadside.

All our skilled technicians have years of experience and are trained to accredited industry standards. Supported by our fleet of dedicated service vehicles that are comprehensively equipped with the correct and calibrated tools for every job. We utilise electronic job sheets to instantly share an audit trail of photographs, torque settings and information of all the work performed.

Horndean Tyres invest in the highest levels of compliance to minimise avoidable risk and ensure professional results. We will never compromise on the safety of our employees, our customers, and other road users.

ISO 9001 Quality Management System

Horndean Tyres have always placed quality at the heart of everything we do. Our comprehensive procedures and policies have been independently assessed and awarded ISO 9001 Quality Management certification.

Our ISO 9001 certification underlines our commitment to customer satisfaction, while always complying with regulations and specifications. We continuously challenge ourselves to improve our services to meet or exceed the expectations of our customers.

ISO 14001 Environmental Management System

Horndean Tyres understands the importance of operating in an environmentally responsible and sustainable manner. We have developed robust procedures to measure, manage and reduce the environmental impact across our operations. With continuous improvement at its core, we constantly work to create a more efficient business with less waste.

This Environmental Management System has recently been independently assessed and awarded ISO 14001 certification. We believe this demonstrates our commitment to delivering the highest standards of environmentally responsible fleet tyre management.

SERVICE YOU CAN RELY ON

Contact us for our fully mobile tyre service

Commercial tyre service

Horndean Tyres Ltd

Units 8 & 9, Westfield Industrial Estate

Horndean, Waterlooville PO8 9JX

Telephone 023 9259 4928

Monday to Friday 8:00am-5:30pm

Saturday 8:00am-3:30pm

Across the region

Horndean Tyres are the region’s leading tyre maintenance service for all types of commercial vehicles: HGVs, rigid trucks, tractor units, HGV trailers, PSVs, buses, coaches, vans and light commercial vehicles LCVs. We operate across central southern England including: Aldermaston, Aldershot, Aldsworth, Alton, Andover, Arundel, Ashdean, Basingstoke, Bedhampton, Billingshurst, Birdham, Bishop’s Waltham, Blandford Forum, Blendworth, Bognor Regis, Bordon, Bosham, Bournemouth, Bovington, Brockenhurst, Buriton, Catherington, Chalton, Chandlers Ford, Chichester, Chilgrove, Chilworth, Christchurch, Clanfield, Colden Common, Corsham, Cosham, Cowplain, Dell Quay, Denmead, Downton, Droxford, East Harting, East Lavant, East Meon, Eastleigh, Eastney, Eaststoke, Emsworth, Fair Oak, Fareham, Farlington, Farnborough, Ferndown, Fernhurst, Fishbourne, Fleet, Ford, Fordingbridge, Forestside, Four Marks, Funtingdon, Gosport, Greenham, Hambledon, Havant, Hayling Island, Hedge End, Hilsea, Hook, Horndean, Horton Heath, Idsworth, Kings Worthy, Kingsclere, Knowle, Langstone, Lee on the Solent, Liphook, Liss, Littlehampton, Locks Heath, Lymington, Lyndhurst, Marchwood, Marden, Meonstoke, Middle Wallop, Midhurst, New Alresford, New Milton, Newbury, North Baddesley, North End, Nutbourne, Odiham, Overton, Paulsgrove, Petersfield, Petworth, Poole, Portchester, Porton Down, Portsmouth, Portswood, Prinsted, Pulborough, Purbrook, Rake, Ringwood, Rogate, Romsey, Rowlands Castle, Salisbury, Selborne, Sheet, Shirley, Shirrell Heath, Soberton, South Harting, South Hayling, Southampton, Southbourne, Southsea, Southwick, Stockbridge, Stoke, Storrington, Stubbington, Swanmore, Tadley, Tangmere, Thatcham, Thorney Island, Totton, Twyford, Verwood, Waltham Chase, Wareham, Warsash, Waterlooville, West Ashling, West Marsden, West Meon, West Moors, West Wellow, Westbourne, Whitchurch, Whitehill, Whiteley, Wickham, Widley, Wilton, Wimborne Minster, Winchester, Woolston, Worlds End, Worthing and Yateley.