Comprehensive plant OTR tyre maintenance

Since 1980, Horndean Tyres have focussed on providing the best plant OTR tyre maintenance services to the widest range of heavy plant, earthmovers, industrial equipment and port handling machinery operating across:

- House Builders and House Construction

- Civil Engineering, Earthmoving and Ground Workers

- Boatyards, Leisure Marinas, Dry Stack Facilities and Shipping Ports & Terminals

- Plant Hire Companies

- Industrial Applications, Waste & Recycling Services and Distribution hubs

- Aggregates, Quarrying and Mining

We understand that every business relies on their heavy plant machinery to be operational to perform your daily schedule of work. Horndean Tyres are here to support this mission with the widest range of responsive on-site tyre maintenance for:

- All terrain crane OTR tyres

- Articulated dump truck/ADT OTR tyres

- Asphalt paver OTR tyres

- Backhoe loader OTR tyres

- Bulldozer OTR tyres

- Construction OTR tyres

- Crane OTR tyres

- Dump truck OTR tyres

- Dumper truck OTR tyres

- Earthmovers OTR tyres

- Empty container handler OTR tyres

- Forklift tyres – material handling

- Forklift tyres – high-capacity

- Front loader OTR tyres

- Grader OTR tyres

- Heavy plant OTR tyres

- Industrial equipment tyres

- JCB tyres

- Loader OTR tyres

- Loading shovel OTR tyres

- Mobile crane OTR tyres

- Mobile harbour crane OTR tyres

- Off highway OTR tyres

- Off road truck OTR tyres

- OTR tyres

- Plant OTR tyres

- Port OTR tyres

- Port handling machinery OTR tyres

- Port terminal tractor OTR tyres

- Port terminal trailer OTR tyres

- Reach stacker OTR tyres

- Rigid dumper truck OTR tyres

- Scraper OTR tyres

- Skid steer loader OTR tyres

- Small wheeled loader OTR tyres

- Solid industrial OTR tyres

- Straddle carrier OTR tyres

- Telehandler OTR tyres

- Tyre roller OTR tyres

- Wheeled excavator OTR tyres

Our team of skilled tyre technicians take pride in providing a lifecycle of comprehensive tyre maintenance and tyre services.

- Tyre pressure correction

- Safe puncture repairs

- Vulcanised major repairs

- Turning on the rim

- Wheel rotation

Our responsive on-site plant tyre maintenance is designed to ensure your heavy plant machinery remains operational, safe and working hard.

Simply contact us with the plant tyre maintenance required and we will arrange a convenient appointment to visit. Our team of skilled tyre technicians will rectify the issue at hand and report any additional actions that should be performed before they escalate.

SERVICE YOU CAN RELY ON

Tyre pressure correction

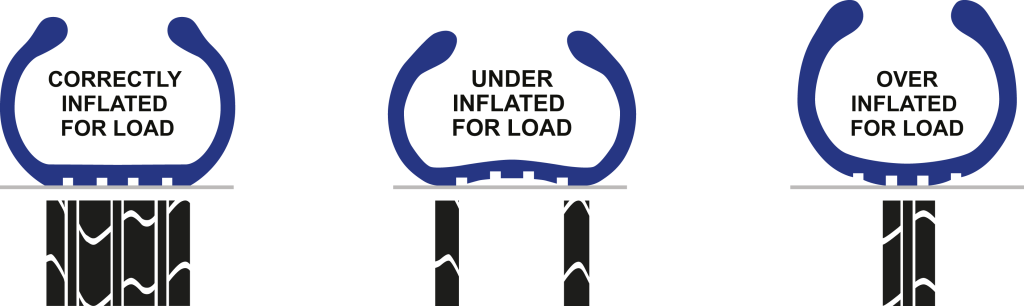

The tyre and wheel assembly is engineered to hold high pressure air in place. All heavy plant machinery is designed to carry exceptionally heavy loads which is all supported on the air pressure inside the tyre. This makes air the critical component in the service life of every plant OTR tyre.

The exceptionally rigid plant OTR tyre construction makes it difficult for operators to detect if the tyre is under-inflated by 20% in their daily walkaround checks. Tyre assemblies and valves can never be totally airtight – you should expect pressure loss every month.

Under-inflated tyres will adversely affect the handling and stability of heavy plant machinery. The plant OTR tyres will generate more friction as they roll which reduces fuel efficiency and leads to an increase in tyre temperature. Left uncorrected, this not only increases tyre wear, but the heat build-up can even lead to premature failure. Over-inflation shortens service life too, as the tyre is susceptible to impact damage and can even burst or deform the wheel rim.

Horndean Tyres can accurately detect incorrect pressure when the plant OTR tyres are cold. Our highly trained tyre technicians will only correct tyre pressure in the safest way – which is critical given the very high air pressures involved. Tyre pressure correction can also highlight slow punctures, which left unchecked will deteriorate and cause unnecessary cost and downtime later.

Safe puncture repairs

Your heavy plant machinery will operate in some of the most hostile environments for pneumatic tyres. Despite being amongst the most durable tyres manufactured, plant OTR tyres remain susceptible to damage from metal objects, rocks, other debris and sharp surfaces, due to transporting their heavy payloads.

The key to any puncture repair or inner tube repair is that the pressure loss is detected quickly. Continuing to operate with under inflated tyres means that the sidewalls will deflect more than they are designed to. This can cause damage to the tyre casing that cannot be repaired.

Our qualified tyre technicians will remove the plant tyre from the wheel rim and give it a detailed inspection internally and externally. If the tyre casing and tread are found to be in good condition, we will repair the puncture in accordance with British Standard AU 159. Horndean Tyres only use high-quality materials to ensure that all puncture repairs are safe and long-lasting.

Puncture repairs to plant OTR tyres are sometimes referred to as cold cure repairs. Our specialist service vehicles are equipped to perform puncture repairs on site.

Vulcanised major repairs

Should your plant OTR tyre damage be more significant than a puncture repair, for example large cuts to the tread or tyre sidewalls, it may be possible to perform a vulcanised repair – also known as a hot repair or major repair.

Our experienced tyre technicians will remove the damaged OTR tyre and identify if they consider a vulcanised repair is possible. Horndean Tyres will then send it away to our specialist tyre partner who will perform extensive checks to determine if a vulcanised repair is possible. The damaged section of the plant OTR tyre will then be carefully rebuilt from the inside using new layers of rubber by qualified personnel. The tyre is then inflated to high-pressure and baked for around 90 minutes in a curing press. This hot bonding process preserves the flexibility and performance of the tyre and is subject to strict British Standards – identical to the production process and Standards of new tyre manufacturing.

A vulcanised repair should allow the plant OTR tyre to continue in operation for the rest of its designed service life. It’s the more environmental and economical solution than replacing the tyre. Radial tyres have a higher success rate for vulcanised repairs than bias tyres.

Turning on the rim

We recommend turning on the rim if the plant OTR tyre has excessive shoulder wear or sidewall abrasion – all caused through routine day-to-day operation.

Turning on the rim involves removing the tyre from the wheel and remounting it with the outer sidewall repositioned to the inside of the wheel. This will even out the tyre wear to enable the tread to come back to a consistent depth and protects the sidewall from further abrasion. Turning on the rim prevents premature replacement of the plant OTR tyre and optimise safety.

Wheel rotation

Our team of skilled tyre technicians will recommend wheel rotation when half of the plant tyres service life has elapsed. Our tyre inspections will identify OTR tyres that can benefit from rotation to even out the wear and extend tyre service life by around 30%.

Wheel rotation involves relocating wheels from one axle to another, and even between heavy plant machinery if suitable and safe. The tyres on the steer axle always experience greater wear as they work hardest. A timely wheel rotation to a slower-wearing axle is more cost effective than letting the tyre wear out and replacement. Similarly, on trailers the tyres on the rear most axle experience the greatest wear. A relocation to the slower-wearing front or middle axle will proactively manage the differing rates of wear.

Safety

Skilled and compliant tyre technicians

Our highly skilled tyre technicians have years of knowledge and expertise gained from working with a diverse selection of heavy plant equipment, industrial equipment, agricultural machinery and port handling. Working from your local Horndean Tyres service centre they will become familiar with your heavy plant. Operationally, this knowledge and understanding will allow them to become a trusted part of your tyre management and maintenance team.

Horndean Tyres invest in training to ensure we are fully compliant with accredited industry standards, including the City & Guilds Licence to Fit programme, the NTDA Licensed Commercial Tyre Technician and REACT Roadside Emergency Licences.

This ensures Horndean Tyres have a consistently skilled workforce that will minimise avoidable tyre risk in your heavy plant equipment, industrial equipment, agricultural machinery and port handling machinery.

Robust and safe procedures

Safety is always Horndean Tyres top concern. Doing things safely means doing things correctly. Our robust work procedures and policies are carefully defined to ensure we consistently perform our tyre services in a rigorous and methodical process.

We create a safe work environment with health and safety compliant to current legislation. The safety of our tyre technicians is paramount as they work across a range of locations, from the relative safety of your premises to construction sites, warehouses to waste management sites, agricultural land to shipping docks & port terminals.

All our skilled technicians have years of experience and are trained to accredited industry standards. Supported by our fleet of dedicated service vehicles that are comprehensively equipped with the correct and calibrated tools for every job. We utilise electronic job sheets to instantly share an audit trail of photographs, torque settings and information of all the work performed.

This high level of compliance is designed to minimise avoidable risk and ensure professional results – driving our commitment to continual improvement. We will never compromise on the safety of our employees, our customers, and others in the area.

ISO 9001 Quality Management System

Horndean Tyres have always placed quality at the heart of everything we do. Our comprehensive procedures and policies have been independently assessed and awarded ISO 9001 Quality Management certification.

Our ISO 9001 certification underlines our commitment to customer satisfaction, while always complying with regulations and specifications. We continuously challenge ourselves to improve our services to meet or exceed the expectations of our customers.

ISO 14001 Environmental Management System

Horndean Tyres understands the importance of operating in an environmentally responsible and sustainable manner. We have developed robust procedures to measure, manage and reduce the environmental impact across our operations. With continuous improvement at its core, we constantly work to create a more efficient business with less waste.

This Environmental Management System has recently been independently assessed and awarded ISO 14001 certification. We believe this demonstrates our commitment to delivering the highest standards of environmentally responsible OTR tyre management.

SERVICE YOU CAN RELY ON

Contact us for our fully mobile tyre service

Plant tyre service

Horndean Tyres Ltd

Units 8 & 9, Westfield Industrial Estate

Horndean, Waterlooville PO8 9JX

Telephone 023 9259 4928

Monday to Friday 8:00am-5:30pm

Saturday 8:00am-3:30pm

Across the region

Horndean Tyres are the region’s leading plant OTR tyre maintenance service for all types of all terrain cranes, articulated dump trucks/ADT, asphalt pavers, backhoe loaders, bulldozers, cranes, dump trucks, dumper trucks, earthmovers, empty container handlers, forklifts– material handling, forklifts – high-capacity, front loaders, graders, JCBs, loaders, loading shovels, mobile cranes, mobile harbour cranes, port handling machinery, port terminal tractors, port terminal trailers, reach stackers, rigid dumper trucks, scrapers, skid steer loaders, small wheeled loaders, straddle carriers, telehandlers, tyre rollers and wheeled excavators. We operate across central southern England including: Aldermaston, Aldershot, Aldsworth, Alton, Andover, Arundel, Ashdean, Basingstoke, Bedhampton, Billingshurst, Birdham, Bishop’s Waltham, Blandford Forum, Blendworth, Bognor Regis, Bordon, Bosham, Bournemouth, Bovington, Brockenhurst, Buriton, Catherington, Chalton, Chandlers Ford, Chichester, Chilgrove, Chilworth, Christchurch, Clanfield, Colden Common, Corsham, Cosham, Cowplain, Dell Quay, Denmead, Downton, Droxford, East Harting, East Lavant, East Meon, Eastleigh, Eastney, Eaststoke, Emsworth, Fair Oak, Fareham, Farlington, Farnborough, Ferndown, Fernhurst, Fishbourne, Fleet, Ford, Fordingbridge, Forestside, Four Marks, Funtingdon, Gosport, Greenham, Hambledon, Havant, Hayling Island, Hedge End, Hilsea, Hook, Horndean, Horton Heath, Idsworth, Kings Worthy, Kingsclere, Knowle, Langstone, Lee on the Solent, Liphook, Liss, Littlehampton, Locks Heath, Lymington, Lyndhurst, Marchwood, Marden, Meonstoke, Middle Wallop, Midhurst, New Alresford, New Milton, Newbury, North Baddesley, North End, Nutbourne, Odiham, Overton, Paulsgrove, Petersfield, Petworth, Poole, Portchester, Porton Down, Portsmouth, Portswood, Prinsted, Pulborough, Purbrook, Rake, Ringwood, Rogate, Romsey, Rowlands Castle, Salisbury, Selborne, Sheet, Shirley, Shirrell Heath, Soberton, South Harting, South Hayling, Southampton, Southbourne, Southsea, Southwick, Stockbridge, Stoke, Storrington, Stubbington, Swanmore, Tadley, Tangmere, Thatcham, Thorney Island, Totton, Twyford, Verwood, Waltham Chase, Wareham, Warsash, Waterlooville, West Ashling, West Marsden, West Meon, West Moors, West Wellow, Westbourne, Whitchurch, Whitehill, Whiteley, Wickham, Widley, Wilton, Wimborne Minster, Winchester, Woolston, Worlds End, Worthing and Yateley.